1989year

In 2019, we started producing mounting cable. It is used in industrial construction and in the oil and gas industry. This gave us an opportunity to work with the major corporations. To find new big customers we decided to take part in the only cable industry event in Russia – Cabex International Exhibition. Our stand attracted a lot of visitors, as well as reporters from Ruscable.ru, the leading cable industry online media.

The year of 2019 finished with an opening of the new production shop equipped with:

-

extrusion line for covering cable with PVC and halogen-free sheaths,

-

5 fine wire drawing machines,

-

fully-automatic winders,

-

20 braiders, 4 of which can braid the cable not only with copper wire but also with steel wire armor.

1999year

In 1999, the plant moved to our own 15000m2 production site in the industrial area of Smolensk. It allowed us to expand the product range considerably. We started producing all kinds of wires and cords for home appliances, fire resistant, power and control cables including armored ones.

2013year

In 2013, the VOLTA® trademark was registered. Our customers associate this logo with great experience and time-tested quality guaranteed by thorough monitoring of each manufacturing stage:

After passing all the tests successfully the goods are distributed to the customers with the VOLTA® logo and quality certificates. We pay special attention to the package as its reliability guarantees product safety.

In 2013, we set up the Sales Department. When hiring managers, we don’t make their sales skills a priority. We look for experts in the cable industry who are willing to look into a client's task and solve it efficiently. That's why in the sales team we have former factory workers, technology officers, and installers.

2015year

In 2015, we started waste-free production by launching several cable waste processing lines. It allowed us to reduce the cost and price of the finished product.

Also a PVC flooring production area was put into operation. Initially, we assumed to produce interlocking floor tiles for our own needs. But the demand for the product turned out to be very high, so we started selling it. Dirt-proof interlocking flooring is indispensable for a warehouse, a plant, a car wash, a car service station, a garage, and a gym.

In 2015, the smart warehouse management system was introduced. Due to electronic stock-in/stock-out records we're at any time aware of the amount of raw materials and finished products available. We manage the stocks in response to demand and process orders faster than our competitors.

2019year

In 2019, we started producing mounting cable. It is used in industrial construction and in the oil and gas industry. This gave us an opportunity to work with the major corporations. To find new big customers we decided to take part in the only cable industry event in Russia – Cabex International Exhibition. Our stand attracted a lot of visitors, as well as reporters from Ruscable.ru, the leading cable industry online media.

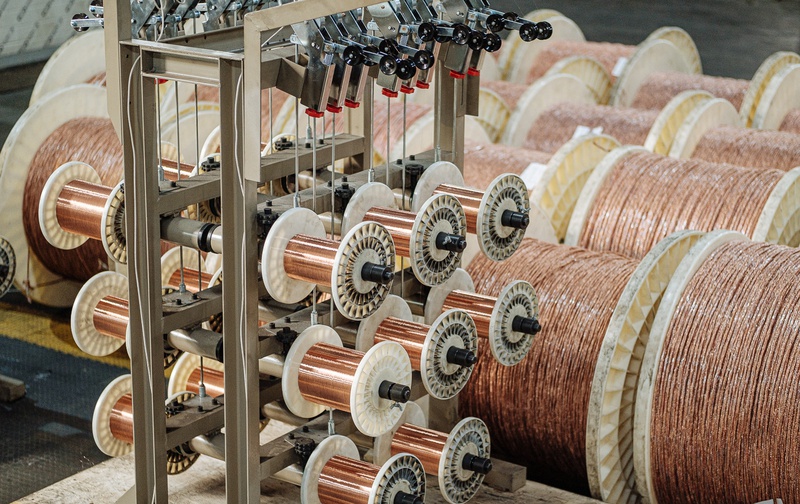

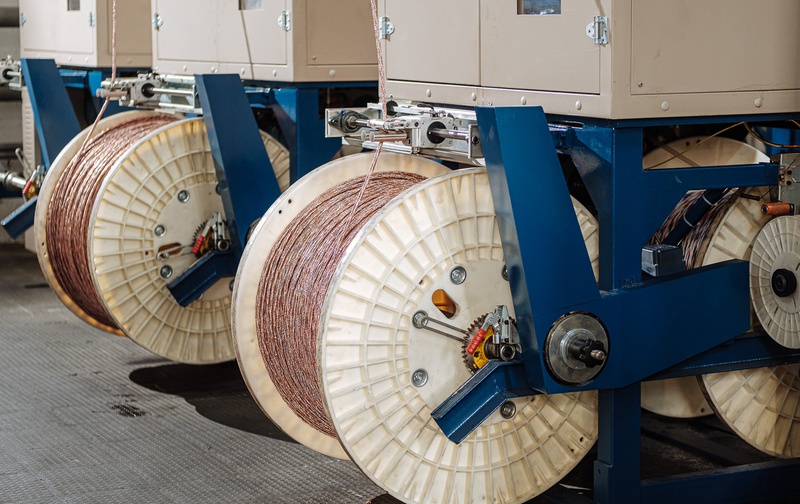

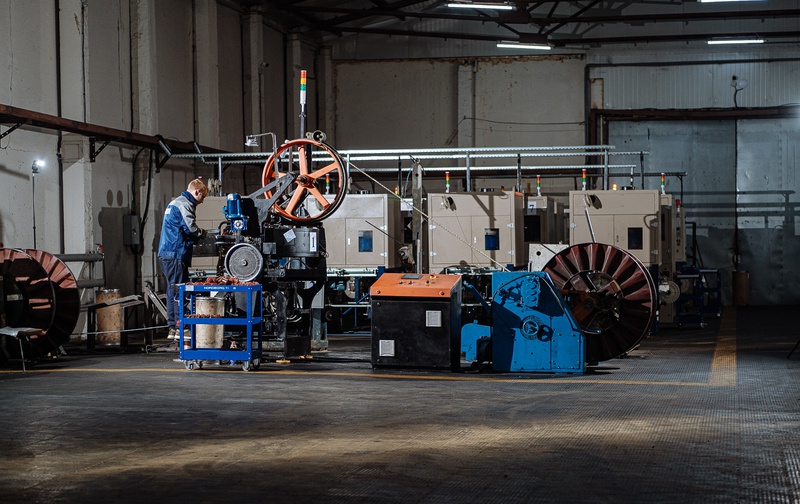

The year of 2019 finished with an opening of the new production shop equipped with:

-

extrusion line for covering cable with PVC and halogen-free sheaths,

-

5 fine wire drawing machines,

-

fully-automatic winders,

-

20 braiders, 4 of which can braid the cable not only with copper wire but also with steel wire armor.

2020year

Declaration of conformity of products to the TR EAEU 037/2016

On March 31, 2020 we registered the Declaration of conformity of products to the TR EAEC 037/2016 «On the Restriction of the Use of Hazardous Substances in Electrical and Radio Electronics products». This is a mandatory document that confirms the conformity of products to the established requirements of the Eurasian Economic Union. The technical regulation is designed to ensure the protection of human life and health, the environment, as well as to prevent actions that would mislead consumers (users) of electrical engineering and radio electronics products about the content of hazardous substances in them.

Laboratory

A new workshop with a testing laboratory for input control of raw materials and output control of products was put into operation. The workshop is equipped with modern laboratory devices, as well as with a new site for testing and video recording of the tests performed. We developed and implemented a procedure of video recording – collection and storage of information on the process of product acceptance and test results. Since then, video recording has been continuously performed along with the existing procedure for collecting and storing arbitration samples of manufactured products.

2021year

Implementation of a quality management system at the enterprise

Availability of a working quality management system is a guarantee of growth and systematic development of the enterprise. Together with the company STC ALPHA REGISTR LLC we trained the personnel in the work and basic principles of the system and received a certificate of compliance with the requirements of GOST R ISO 9001-2015.

Industry 4.0 and Industry 5.0

As part of the digitalization of the enterprise, together with the company KL Business Solutions we gave a start to a huge long-term project to implement industry-specific software products for monitoring and production management at the enterprise. In the very near future, this will combine the speed and efficiency of machine technology with the ingenuity and talents of our colleagues.

2022year

Joining the Electrocable Association (AEC)

The Association has brought together high-level professionals. Over the past few years, our company has made serious technical, managerial and infrastructural advances, especially in matters of digitalization of technological processes. Due to high rates of implementation, we have taken leading positions in certain segments of the market. Joining AEC will allow us to make a significant contribution to the development of the Russian cable industry.

CableDesigner implementation

As part of the company's digitalization work, a specialized software product CableDesigner was implemented for design and technological preparation of production.

Waste recycling license

The Federal Service for Supervision of Natural Resource Usage (Rosprirodnadzor) granted us a license for collection, transportation, treatment, recycling, neutralization and disposal of waste of hazard classes I-IV. This is the result of a long systematic work to implement our program of recycling waste from cable industry enterprises.

2023year

Development of a new technical specification for mounting cables

At the beginning of the year, we developed a new technical specification for a group of universal mounting cables of the widest range of applications. In this document, we tried to unite not only a wide range of cables for various purposes, but also described in detail all the nuances of their manufacture. This is very important for the result predictability in the production. We paid special attention to the principle of branding and maintained continuity concerning the semi-finished product and final product names. Together with the Optik-Energo group of companies, in particular, with Optikenergo Testing Center LLC, we certified our products.

IoT implementation

As part of the company's digitalization efforts, we implemented a system for monitoring and forecasting the technical condition of equipment.